Time:2024-08-08Views:1

Injection mold manufacturing for home appliances is a vital component of the consumer goods industry, producing the complex plastic parts that make up everyday items such as kitchen appliances, cleaning equipment, and electronic devices. The process begins with the design phase, where engineers use advanced CAD software to create detailed blueprints of the molds. This phase is critical as it sets the foundation for the functionality and aesthetics of the final product. Design considerations include factors such as part geometry, material selection, and mold complexity, all of which impact the manufacturing process and the quality of the finished parts.

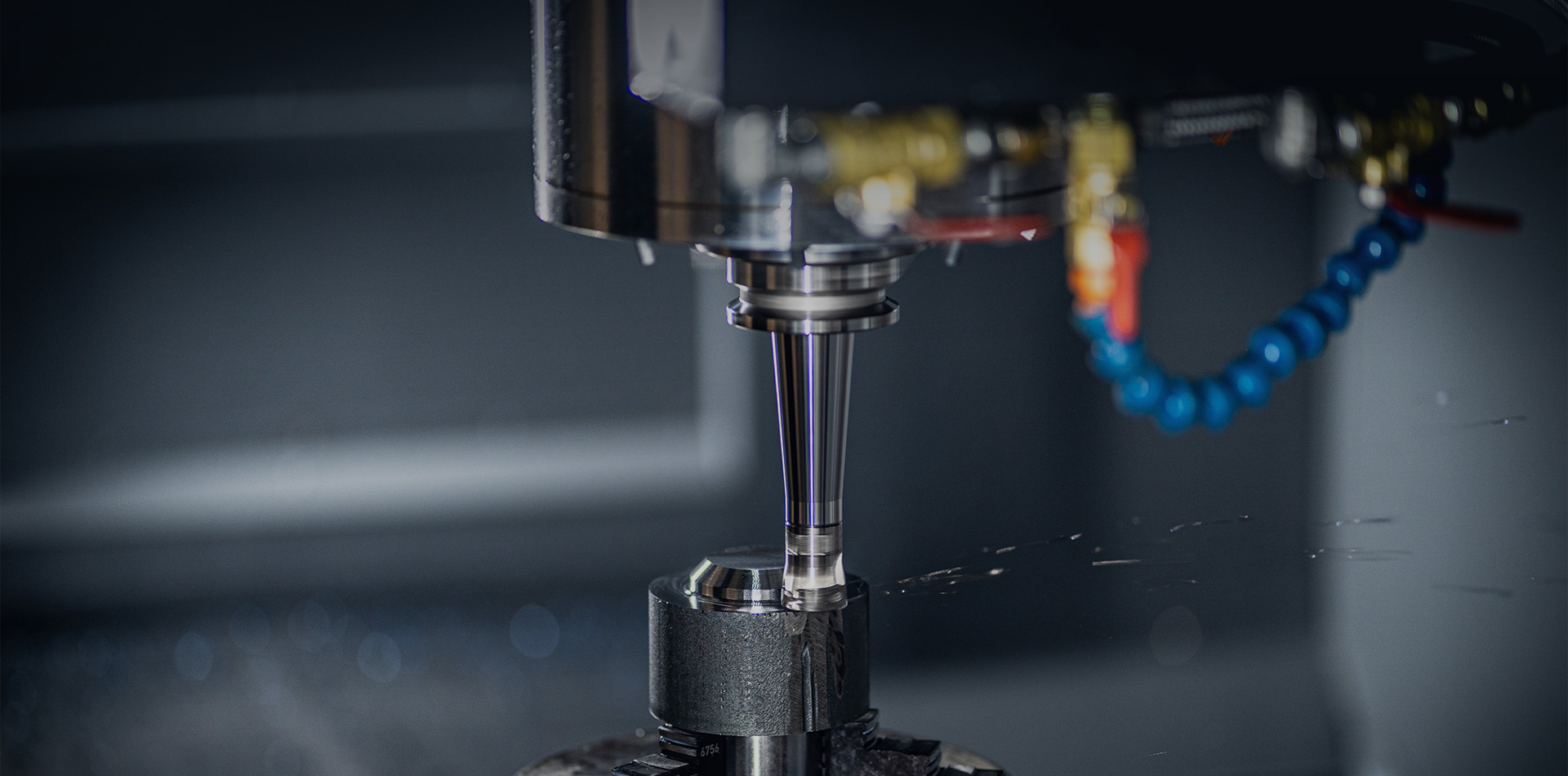

Following the design phase, the molds are fabricated using high-quality materials such as steel or aluminum, chosen for their durability and ability to maintain dimensional stability over time. CNC machining and other precision manufacturing techniques are employed to create the intricate features and contours of the mold cavities. Each mold is then meticulously inspected to ensure that it meets the required specifications and tolerances.

Once the molds are completed, they are installed in injection molding machines where they are used to produce the plastic components for home appliances. Molten plastic is injected into the mold cavities under high pressure, where it cools and solidifies into the desired shape. The finished parts are then ejected from the mold and undergo secondary operations such as trimming, decorating, and assembly. Quality control measures are implemented at every stage to ensure that the components are free from defects and meet the required standards for performance and durability.

In conclusion, injection mold manufacturing for home appliances is a sophisticated process that combines advanced technology, skilled craftsmanship, and rigorous quality control to produce high-quality plastic components. These components are essential for the function and appearance of home appliances, ensuring that they meet the demands and expectations of modern consumers. By continually innovating and improving manufacturing techniques, the industry is able to deliver reliable and efficient products that enhance the quality of life for people around the world.

Provide free proofing service

0755-23244922 / 23400063

7*24 full service

Video live demonstration